Iningi labangane abasha bokubonisa i-LED banelukuluku lokufuna ukwazi, kungani ekuvakasheni komhlangano wokusebenzela wokubonisa ama-LED amaningi, kudingeka balethe izembozo zezicathulo, indandatho kagesi, ukugqoka izingubo zikagesi nezinye izinto zokuzivikela. Ukuze siqonde le nkinga, kufanele sikhulume ngolwazi oluhlobene nokuvikelwa kukagesi omile ekukhiqizeni nasekuthuthweni kwesibonisi se-LED. Eqinisweni, izibonisi eziningi ze-LED zibonakala zifile noma zingakhanyi, ikakhulukazi ngenxa kagesi omile.

Imithombo kagesi omile ekukhiqizeni izibonisi ze-LED:

1. Izinto, izinto zokwakha.

2. Iphansi, amatafula okusebenza nezihlalo.

3. Izingubo zokusebenza nezitsha zokupakisha.

4. Indawo ependiwe noma ene-wax, izinto eziphilayo kanye ne-fiberglass.

5. Iphansi eliwukhonkolo, iphansi elipendiwe noma eline-wax, amathayela epulasitiki noma isikhumba saphansi.

6. Izingubo zokusebenza ze-Chemical fibre, izicathulo zokusebenza ezingaqhubeki, izingubo zokusebenza zikakotini ezihlanzekile.

I-7, ipulasitiki, amabhokisi okupakisha, amabhokisi, izikhwama, amathreyi, i-foam liner.

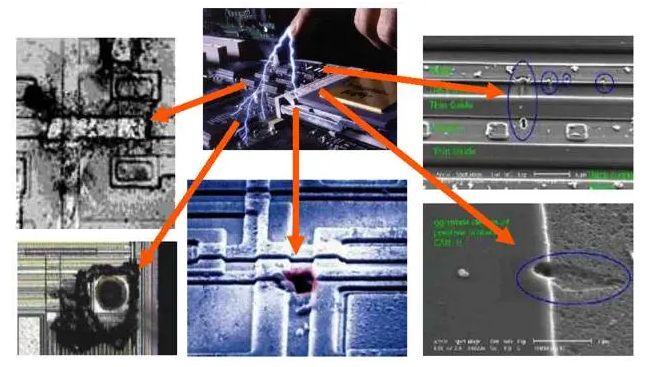

Uma i-anti-static ishaywa indiva nganoma isiphi isikhathi ekukhiqizeni, izodala ukuthi amadivayisi kagesi angasebenzi kahle noma aze awalimaze. Uma amadivaysi e-semiconductor ebekwa ngawodwana noma elayishwa kusekethe, ngisho noma engenawo amandla, ukulimala okungapheli kulawa madivayisi kungase kwenzeke ngenxa kagesi omile. Njengoba wazi kahle, i-LED iwumkhiqizo we-semiconductor, uma i-voltage phakathi kwezikhonkwane ezimbili noma ngaphezulu ze-LED idlula amandla okuqhekeka kwe-dielectric yengxenye, izodala umonakalo engxenyeni. Uma ungqimba lwe-oxide luba mncane, kuba mkhulu ukuzwela kwe-LED kanye nomshayeli we-IC kugesi omile. Isibonelo, ukuntuleka kokugcwala kwe-solder, izinkinga ngekhwalithi ye-solder ngokwayo, njll., kungadala izindlela eziyingozi zokuvuza ezingabangela umonakalo omkhulu.

Olunye uhlobo lokwehluleka lubangelwa lapho izinga lokushisa le-node lidlula indawo yokuncibilika ye-silicon ye-semiconductor (1415°C). Amandla ashaywayo kagesi omile angakhiqiza ukushisisa kwendawo, ukuze kwenzeke iphutha elingena ngokuqondile esibanini naku-IC. Lokhu kwehluleka kungenzeka noma ngabe i-voltage ingaphansi kwe-voltage yokuqhekeka kwe-dielectric. Isibonelo esijwayelekile ukuthi i-LED iyinhlanganisela ye-PN ye-diode, i-emitter kanye nesisekelo sokuhlukana phakathi kwenzuzo yamanje kuzoncishiswa kakhulu. I-LED ngokwayo noma isekethe yomshayeli ezinhlobonhlobo ku-IC ngomthelela kagesi omile, ingase ingaveli ngokushesha umonakalo osebenzayo, lezi zingxenye ezingase zibe yingozi ngokuvamile ekusetshenzisweni kwenqubo zizoboniswa kuphela, ngakho-ke umthelela wempilo umkhiqizo we-LED uyabulala.

Inqubo yokukhiqiza isibonisi se-LED iyinqubo eqinile, ecashile, isixhumanisi ngasinye asinakushiywa. Ukuboniswa kokuvikelwa kwe-electrostatic nakho kuyingxenye ebalulekile yokukhiqizwa kwesibonisi se-LED, imboni namanje ayijulile ngokwanele ukuqonda ukuvikelwa kwe-electrostatic, ingasaphathwa eyokuhlangabezana nezidingo zokukhiqizwa kwesibonisi se-LED, kodwa futhi idinga ochwepheshe abengeziwe ukuze baqhubeke nokufunda. futhi nixoxe ndawonye.

Ungavimbela kanjani ugesi omile ekukhiqizeni isibonisi se-LED:

1. Ukusetshenziswa kwabasebenzi besekethe ebucayi kagesi ukuze benze ulwazi lwe-electrostatic kanye nokuqeqeshwa kobuchwepheshe obuhlobene.

2. Ukusungulwa kwendawo yokusebenza emelene ne-static, ukusetshenziswa kwendawo yokukhipha i-static, ibhentshi lokusebenzela eliphikisayo, i-anti-static grounding lead kanye nezinto zikagesi ezilwa nokuqina, futhi kuzoya ekulawuleni umswakama ohlobene ngaphezu kuka-40.

3. Izingozi ezibangelwa ugesi omile ezintweni zikagesi zingadedelwa noma yikuphi ukusuka kumkhiqizi kuya ezintweni ezisesigabeni. Izingozi zibangelwa ukwehluleka okwanele, ukuqeqeshwa okuphumelelayo kanye nokwehluleka kobuqili.Ama-LED angamadivayisi azwelayo.Amawafa e-INGAN avame ukubhekwa "njengakuqala" mayelana nokuba sengozini yokuphazamiseka. Ama-chips e-INGAN ngokuvamile abhekwa "njengakuqala" ngokuya ngokuba sengozini, kuyilapho i-ALINGAPLEDSSHI "ingokwesibili" noma engcono.

4. Amadivayisi alimele e-ESD angabonisa ukufiphala, ukufiphala, ukucisha, i-VF emfushane noma ephansi noma i-VR. Amadivayisi alimele e-ESD akumele adidaniswe nokugcwala kakhulu kwe-elekthronikhi, okufana nalokhu: ngenxa yedizayini yamanje eyiphutha noma idrayivu, i-wafer hookup, isisekelo socingo lwesihlangu noma i-encapsulation, noma ingcindezi evamile ebangelwa imvelo.

5. Izinqubo zokuphepha nokulawula ze-ESD: izinkampani eziningi zikagesi neze-electro-optical zifana kakhulu ne-ESD, futhi zisebenzise ngempumelelo izisetshenziswa zokulawula i-ESD, ukukhohlisa kanye nohlelo olukhulu. Lezi zinhlelo bezisetshenziswa kusukela kudala ukuthola imiphumela yekhwalithi yamathuluzi e-ESD. Isitifiketi se-ISO-9000 siphinde simfake ezinqubweni zokulawula ezijwayelekile.

Isikhathi sokuthumela: Jul-17-2023